Research & Development

Tear Down

Disassembly Provides Insights and Encourages Creativity

By comparing our products to those of other companies, we strive for technical improvements as well as cost-down effects. In this sense, we employ tear down analysis as part of our creative activities. Furthermore, the analysis of HV and EV parts provides us with an understanding of technological trends, which then enables us to come up with concepts and proposals for new products.

In-House Development

Grasping the Future of the Automotive Industry: Departing from Convention

What can KSK do in light of the trend towards electric and self-driving vehicles? We are aiming to establish a research and development environment that is not constrained by specialized fields, but rather one that can tap into the skills and hidden knowledge and senses of all our employees. We will venture into new domains, constantly striving to develop innovative solutions that meet the requirements of our customers.

Test Facilities

Fully-Equipped: Ranging from Development Proposals through to Test Evaluations

Boasting a permanent benchmark room, 3D and 2D CAD, resin molding machine, various test devices, analysis units and test vehicles, we are fully equipped to validate and verify the quality of our designs, and thus we fulfil the requirements of an 'Assembly Warranty Manufacturer'.

Examples of Patents Acquired

Actively Promoting the Acquisition and Effective Use of Intellectual Property

-

Structural Binding of Metal Parts

A method for binding together metal parts of varying hardness. The shaft end of one part is pressed into the stepped hole of another until contact is established. As a result of the pressure, the softer material is made to deform and 'flow', thus creating a mechanical structure that binds the two parts together. The patent covers the structural binding of metal parts. -

Structural Binding of Metal Parts and Device

First a groove is processed into a part made from a hard material. Applying pressure to a softer part, the softer material is made to deform and 'flow' into the groove. 'Plastic-Flow Binding' creates a structural connection between the parts. The patent covers the structural binding of metal parts and the device. -

Folding Gear Shift Lever

A gear shift lever with a holder that connects the upper and lower lever; equipped with a mechanism that allows it to tilt 90° in the selected direction. -

AT Selection Lever

A selection lever for automatic transmissions equipped with a horizontal folding mechanism, based on the gear shift lever for manual transmissions. -

AMT Gear Shift Lever

An AMT (Automated Manual Transmission) gear shift lever integrating a guiding mechanism to guide the movement of the shift lever and a detent mechanism for positioning the shift lever in a single structure. -

One-Motor Shift Control Device

A shift control device that enables shift and select operations with a single electric motor by combining the motor (as power source) with a clutch.

Joint Development between Industry and Academia

Building a more Resilient R&D Framework with Collaboration

In order to create a more tenacious system of research and development, we have established collaborations with research teams of engineering universities. Adding Complementing 'Academic Skills' to with 'Conceptual Skills' and 'Technological Skills', we have ensured that the research experience of engineering universities goes into our product development.

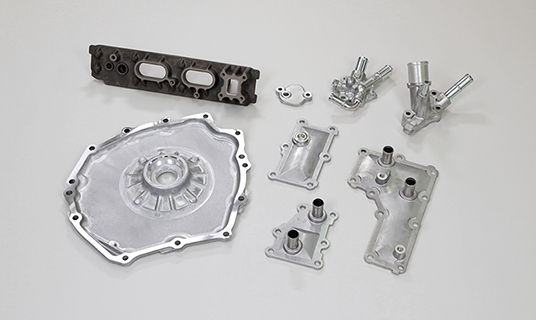

One of our current collaboration projects of collaboration is the to application ofy our plastic plastic-flow binding technology to connecting connect die-cast aluminum parts with plastic components. Another project is involves the to advancement of electrical control technology by means of simulation.

Product Proposal

Development Proposals Reflecting a 'Craftsman-Spirit' Based on Technical Skills

We are the only system supplier in Japan for transmission control systems. From light vehicles ('K-cars') to large trucks, we provide solutions for our customers with an integrated system - from development proposals to product design, analysis and test evaluation. This includes in-house development as well as development by order. AMT gear shift levers and control boxes are also developed within this integrated system.

Basic Research

Kick off for Motor and Motor Control, Thin-wall Casting and Processless Technologies

The 'EV-shift' from gasoline and diesel vehicles to Electric Vehicles (EVs) is accelerating globally, and the automotive industry is facing a once-in-a-century turnaround. KSK is making sure it firmly grasps the changes in order to facilitate the development of new products. To this end, we have launched basic research into motors and motor control technologies, thin-wall casting, and heat dissipation technology.